Brushless Vs Brushed DC Motors: When and Why to Choose

Brushless DC Motors - RapidPower™ Xtreme Brushless DC Servo Motor - ElectroCraft

The Of DC Motors - Brushed & Brushless DC Motors - RS Components

When transforming electricity into mechanical power, brushless motors are more efficient than brushed motors mostly due to the lack of brushes, which lowers mechanical energy loss due to friction. The boosted effectiveness is greatest in the no-load and low-load regions of the motor's efficiency curve. Environments and requirements in which producers utilize brushless-type DC motors consist of maintenance-free operation, high speeds, and operation where sparking is dangerous (i.

Brushless DC Motors

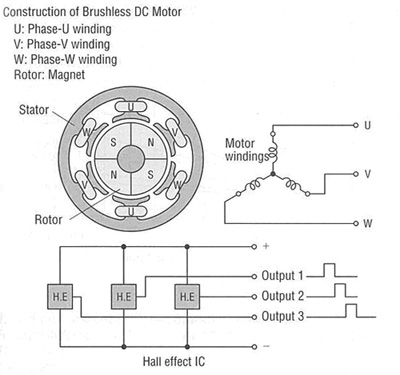

explosive environments) or could affect digitally sensitive devices. The construction of a brushless motor looks like a stepper motor, however the motors have important distinctions due to distinctions in execution and operation. While stepper motors are frequently stopped with the rotor in a specified angular position, a brushless motor is normally intended to produce continuous rotation.

The Definitive Guide to All Brushless DC Motors - Portescap

Both a stepper motor and a properly designed brushless motor can hold limited torque at absolutely no RPM. Controller implementations [edit] Due to the fact that the controller carries out the standard brushes' performance it needs to understand the rotor's orientation relative to the stator coils. This is automated in a brushed motor due to the fixed geometry of the rotor shaft and brushes.

Others determine the back-EMF in the undriven coils to presume the rotor position, removing the requirement for separate Hall effect sensors. These are therefore often called sensorless controllers. Controllers that notice rotor position based upon back-EMF have additional challenges in initiating movement due to the fact that no back-EMF is produced when the rotor is fixed.

Brushless DC Motors - BLDC Motors from NANOTEC

Fascination About Global Brushless DC (BLDC) Motors Market Report 2020-2028:

This can trigger the motor to run in reverse briefly, including a lot more intricacy to the start-up series. Other sensorless controllers are capable of measuring winding saturation triggered by the position of the magnets to presume the rotor position. [] A typical controller contains three polarity-reversible outputs controlled by a reasoning circuit.

More advanced controllers utilize a microcontroller to handle velocity, control motor speed and fine-tune efficiency. Related Source Here of brushless DC motors are the motor constants K T \ displaystyle K _ T (torque constant) and K e \ displaystyle K _ e (back-EMF continuous, likewise called speed consistent K V = 1 K e \ displaystyle K _ V = 1 \ over K _ e ).